Friction Coefficient Test

Hardide coatings have a low dry friction coefficient as proven in the ESTL Friction Coefficient Tests

Due to its homogeneous and uniform nanostructure, the Hardide coating polishes as it wears. This offers a distinct advantage over cemented carbide or spray coatings where the soft matrix wears away first, causing the surface finish to degrade and the hard carbide particles to prematurely abrade the material that they run against – sometimes known as the “cheese-grater” effect.

When compared to diamond or diamond-like coatings in similar applications, the Hardide coating demonstrates superior performance as it can be applied up to ten times thicker, be machined and it retains lubricating oils like other metals.

Hardide coatings perform very well when in contact with softer materials such as elastomeric seals, packing and metals ranging from brass to inconel.

Friction Coefficient Testing

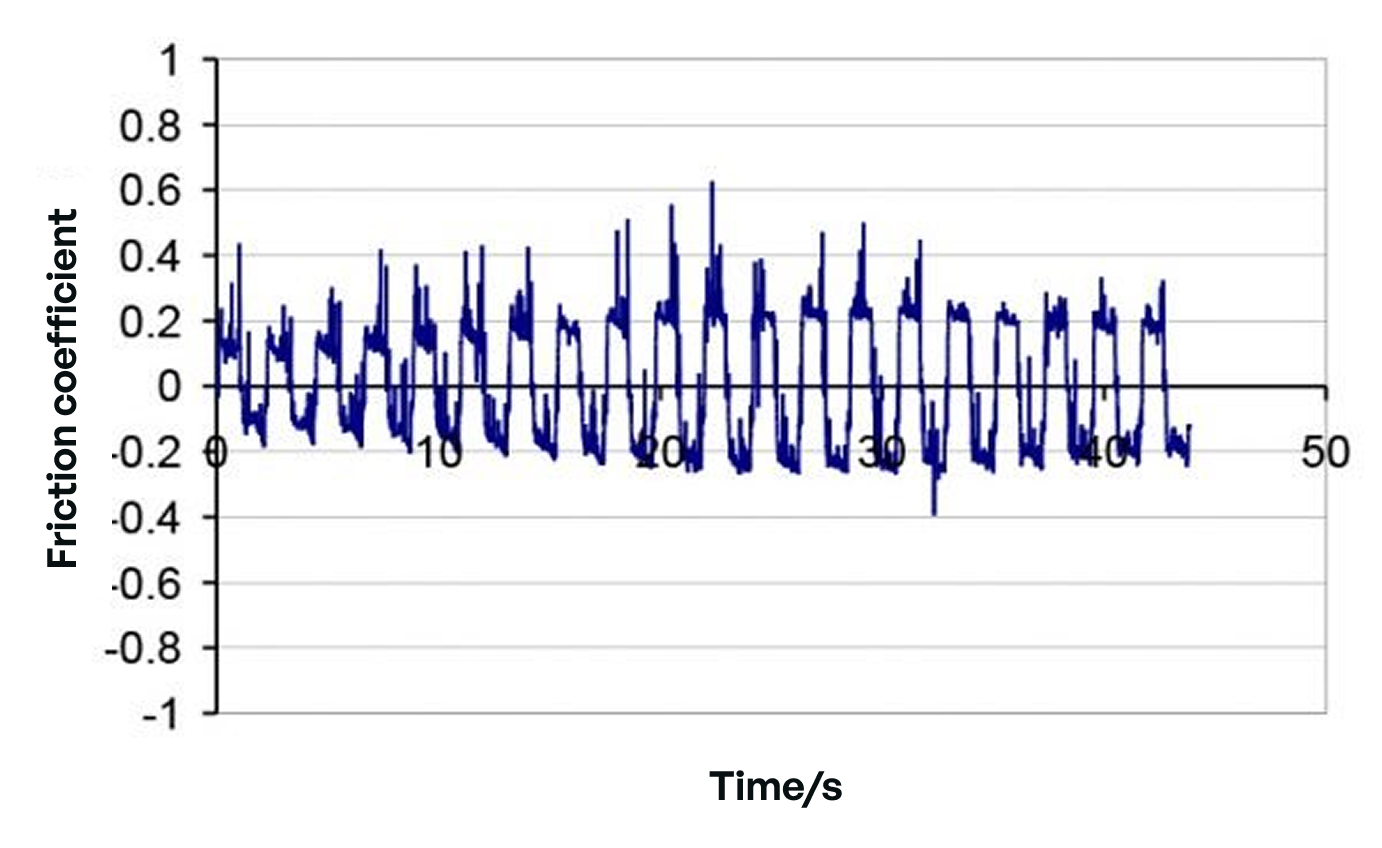

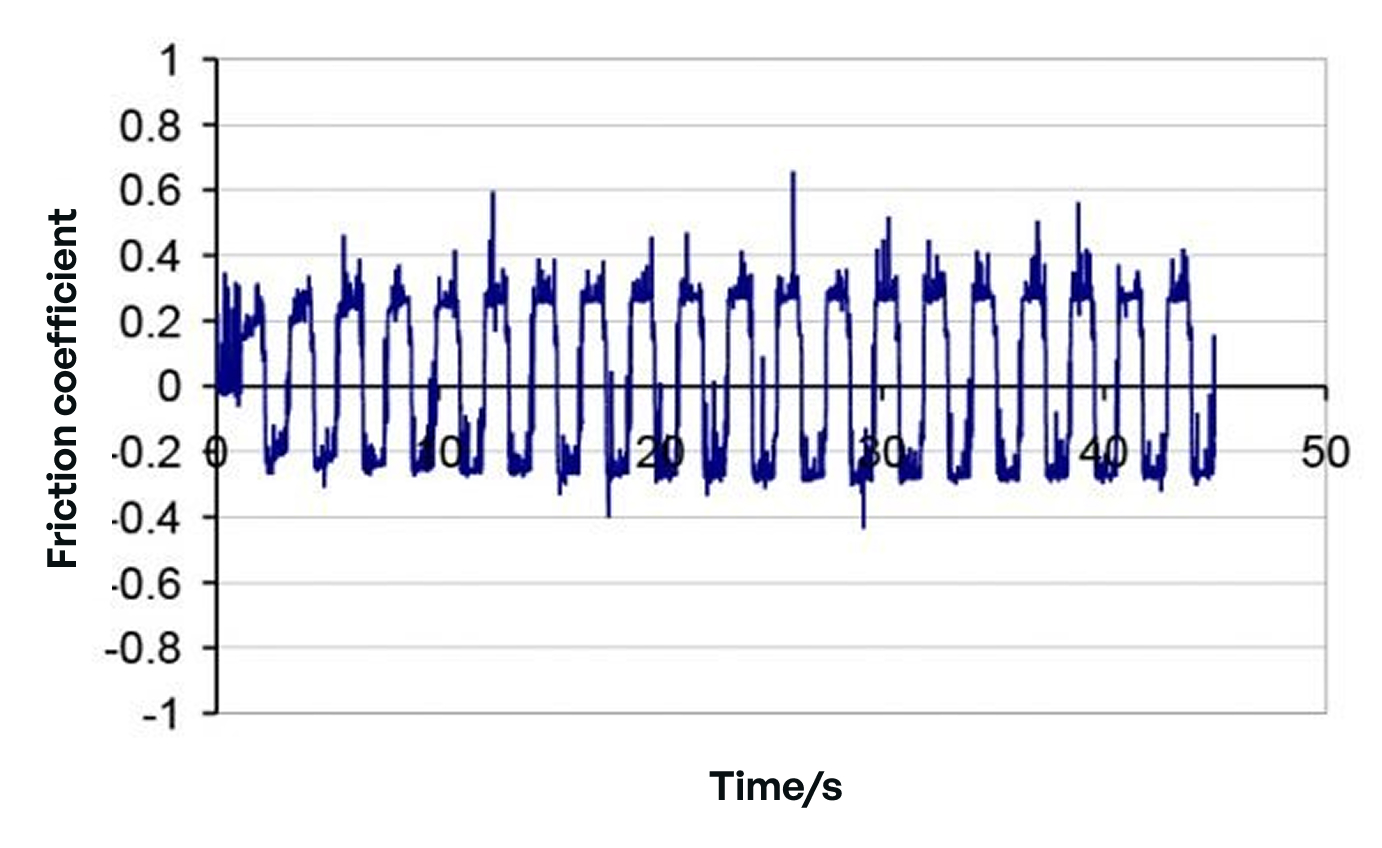

Tests performed using pin-on-disc tribometer in air and vacuum:

Track radius = 10mm

Stroke length = 10mm

Speeds = 0.01 and 0.1 ms-1

Normal load = 5N

| Test | Disc | Pin | Environment | Static Friction | Average dynamic friction coefficient | Peak friction | Variance |

|---|---|---|---|---|---|---|---|

| 3A | Ti-alloy – WC coated (polished) | Ti | Air | 0.17 | 0.17 | 0.64 | 0.004 |

| 15A | Ti-alloy – WC coated (polished) | Ti | Vacumm | 0.15 | 0.24 | 0.65 | 0.004 |

Related Resources

Rotating Bend Fatigue Test

Independent testing has proven that the Hardide-A coating improves the fatigue life…

Read More →Impact Resistant & Scratch Test

Hardide coatings are deposited as a uniform, crack-free coating that is tough…

Read More →NACE TM0177 Stress Test

The independent NACE TM0177 tests has proven the resistance of Hardide coating…

Read More →