Acid Passivation

Industry-grade passivation with precision and consistency

Achieving a flawless coating begins with the foundation of clean, contaminant-free surfaces. At Hardide, we offer a comprehensive cleaning and degreasing service that ensures every component is meticulously prepared for optimal coating adhesion and reliable in-service performance.

Precision coatings demand pristine surfaces. Any trace of oil, grease or oxidation can reduce coating adhesion and compromise long-term durability. Our cleaning and degreasing services are engineered to deliver total surface preparation for the highest coating integrity, especially on complex components.

The Hardide advantage

We engineer acid passivation as part of a larger system of high-performance surface treatments. Whether your component will operate in marine, chemical, or aerospace conditions, our passivation service provides a critical barrier against corrosion from moisture, salt, and harsh chemicals.

Tightly controlled process parameters for reliable, repeatable results

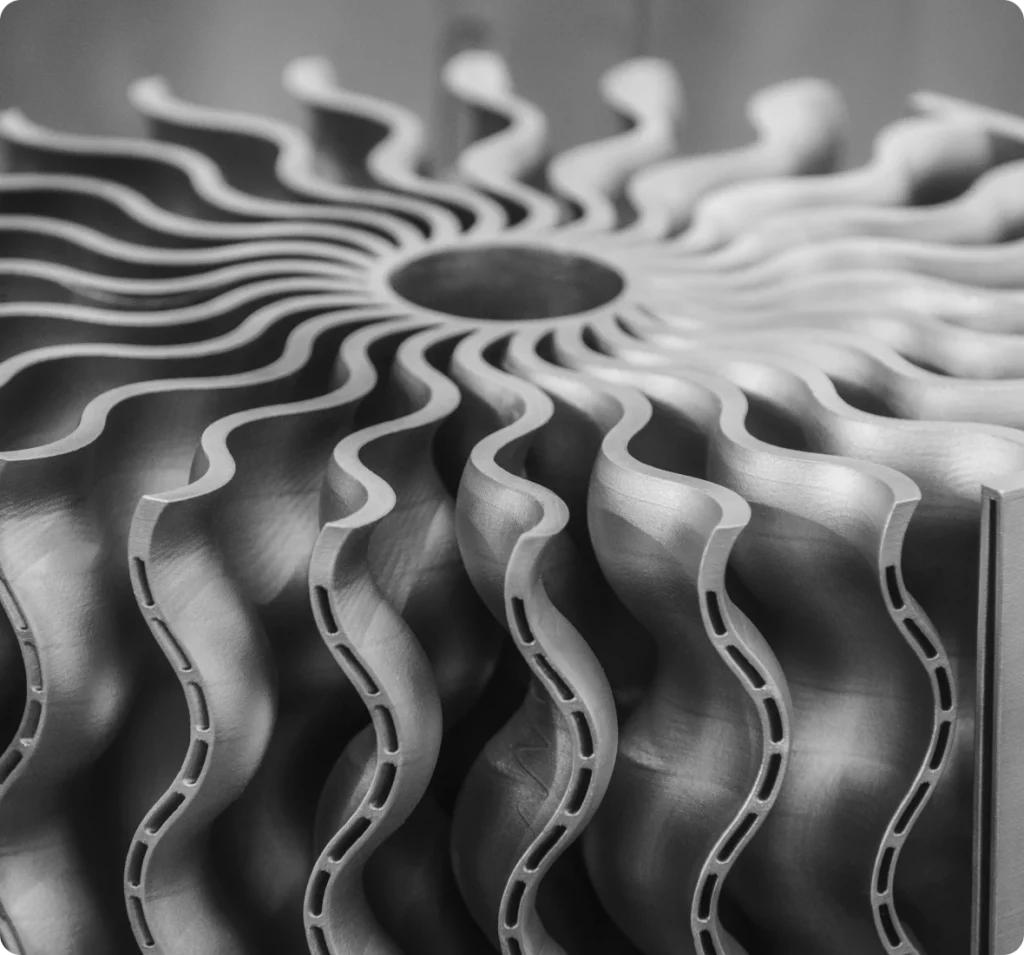

Compatible with a wide range of material grades and complex geometries

Optimised for integration with advanced coatings, including Hardide CVD

Available as a standalone service or pre-coating preparation

Results you can trust

Hardide’s acid passivation provides a cleaner, more corrosion-resistant surface without affecting the base metal or part dimensions. Components treated through our passivation process show prolonged life, reduced maintenance demands, and enhanced performance in hostile environments.

By promoting a uniform oxide layer, our passivation also improves the consistency of any coating that follows, reducing the risk of under-film corrosion or adhesion failures.

Ideal for a variety of applications

Whether you’re seeking to extend service life, reduce downtime or meet strict environmental performance standards, Hardide’s acid passivation service ensures reliable performance in a variety of environments and applications.

- Aerospace and defence components exposed to high humidity or fluid ingress

- Precision-engineered parts in offshore and chemical processing systems

- Stainless steel surfaces needing enhanced corrosion reliability before coating

Ready for Precision-Prepared Surfaces?

Our advanced cleaning and degreasing services are engineered for coating integrity and in-service reliability. Whether you’re dealing with intricate geometries or preparing for Hardide coatings, we’re here to ensure your components meet the highest standards of cleanliness. Speak with our experts to explore how we can support your coating or inspection process with precision surface preparation.

;)