Laboratory Services

Precision analysis and testing, trusted by industry leaders

Behind every high-performance coating is rigorous testing, and we bring that same level of precision and care to support your wider material challenges. Our in-house laboratory is an expert extension of your engineering team, providing the data and insight needed to solve complex material and performance questions.

Trusted expertise, industry-leading capability

Our laboratory is accredited to NADCAP and AS9100 standards with more than four decades of metallurgical and chemical experience. We work with customers across a wide range of sectors who trust us for the accuracy and repeatability of our analysis as well as our coating solutions. Our team delivers results that stand up to scrutiny, whether you need to verify coating adhesion or simulate harsh operating environments.

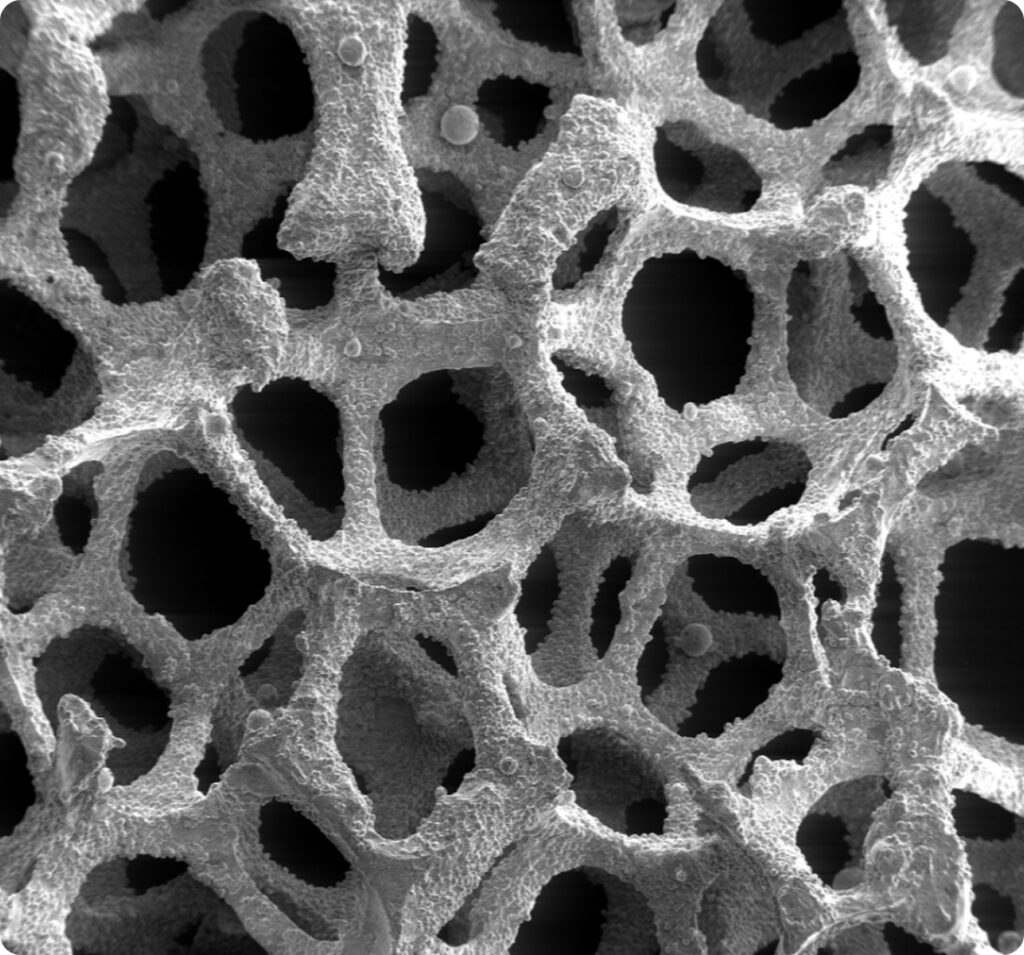

Metallography and microstructure revealed

Material performance starts at the microscopic level. That’s why our laboratory combines advanced preparation and state-of-the-art imaging to uncover the detail others might miss. Every specimen is prepared to exacting standards through our full metallographic support:

- Large-scale and precision sectioning for a wide range of materials and geometries

- Hot compression and cold mounting for micro-specimens

- Semi-automatic grinding and polishing down to sub-micron finishes

- Ultrasonic cleaning in temperature-controlled baths

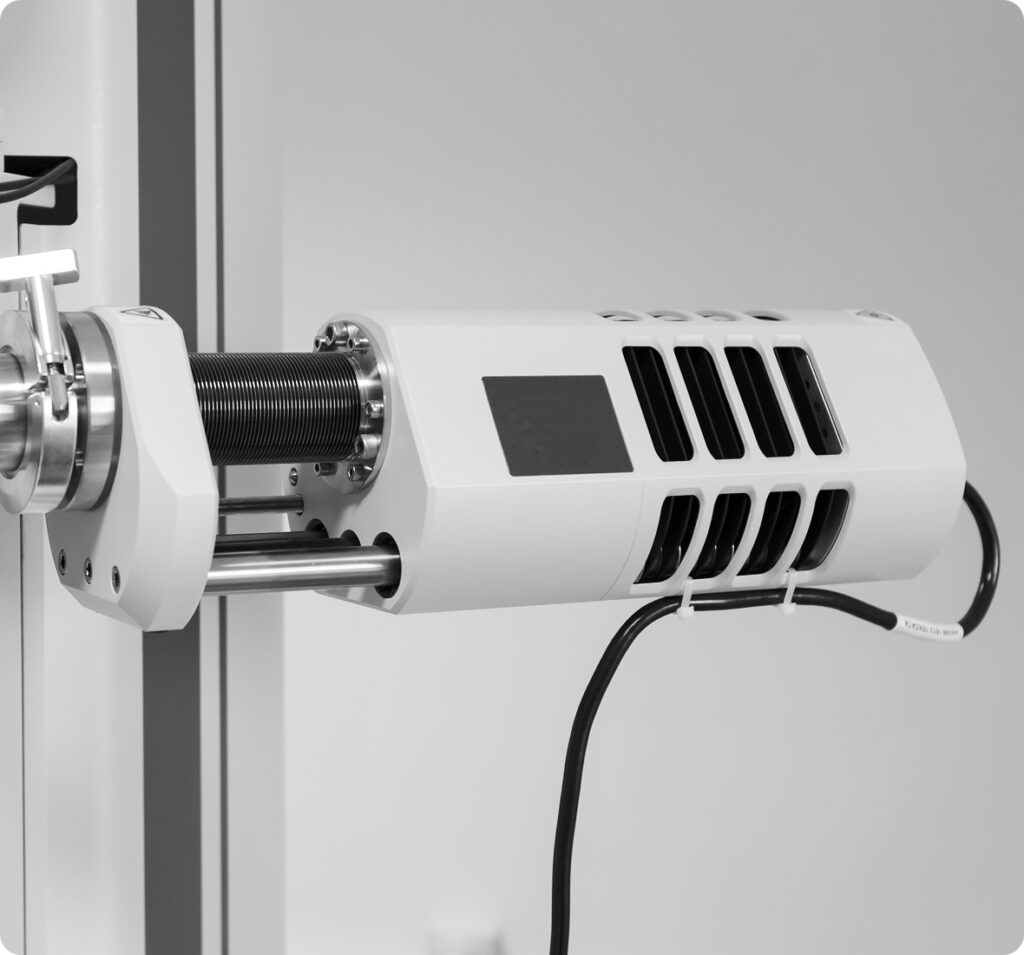

Comprehensive surface and materials characterisation

We go deeper than surface level. Using scanning electron microscopy (SEM) with energy dispersive X-ray (EDX) analysis, optical microscopy and portable XRF technology, our team examines coatings, interfaces and substrates in fine detail. We measure hardness, thickness, composition and roughness, equipping you with actionable data to refine designs and drive innovation. Our full range of testing is as follows:

- Scanning Electron Microscopy (SEM) with Energy Dispersive X-Ray (EDX) analysis

- X-Ray Fluorescence (XRF) for material composition and plating thickness, portable for on-site testing

- Inverted optical microscopy with Bright Field, Dark Field, Polarised and Differential Interference Contrast techniques

- Cross-sectional coating, interface and substrate evaluation

- Vickers Microhardness testing (10g–2kg load range)

- Surface roughness and profilometry

Corrosion and environmental testing

Our corrosion and environmental testing services replicate real-world conditions to ensure your materials meet performance requirements long before they enter service.

- Accelerated salt spray testing to ASTM B117, ISO 9227 and IEC 60068-2-11

- Wet chemical analysis and titrimetric evaluation

- Bespoke test regimes to meet specific project requirements

An extension of your quality assurance

At Hardide, laboratory testing is a cornerstone of our dedication to reliability. Our customers value our commitment to consistency and our collaborative approach, helping you interpret the results and make informed decisions for your materials, components and coatings. Whether as a standalone service or integrated with our coating solutions, Hardide Laboratory Services are here to give you confidence and a competitive edge. Get in touch to discuss how we can support your next project.