Electroless Nickel Plating (ENP)

Performance driven protection, without compromise

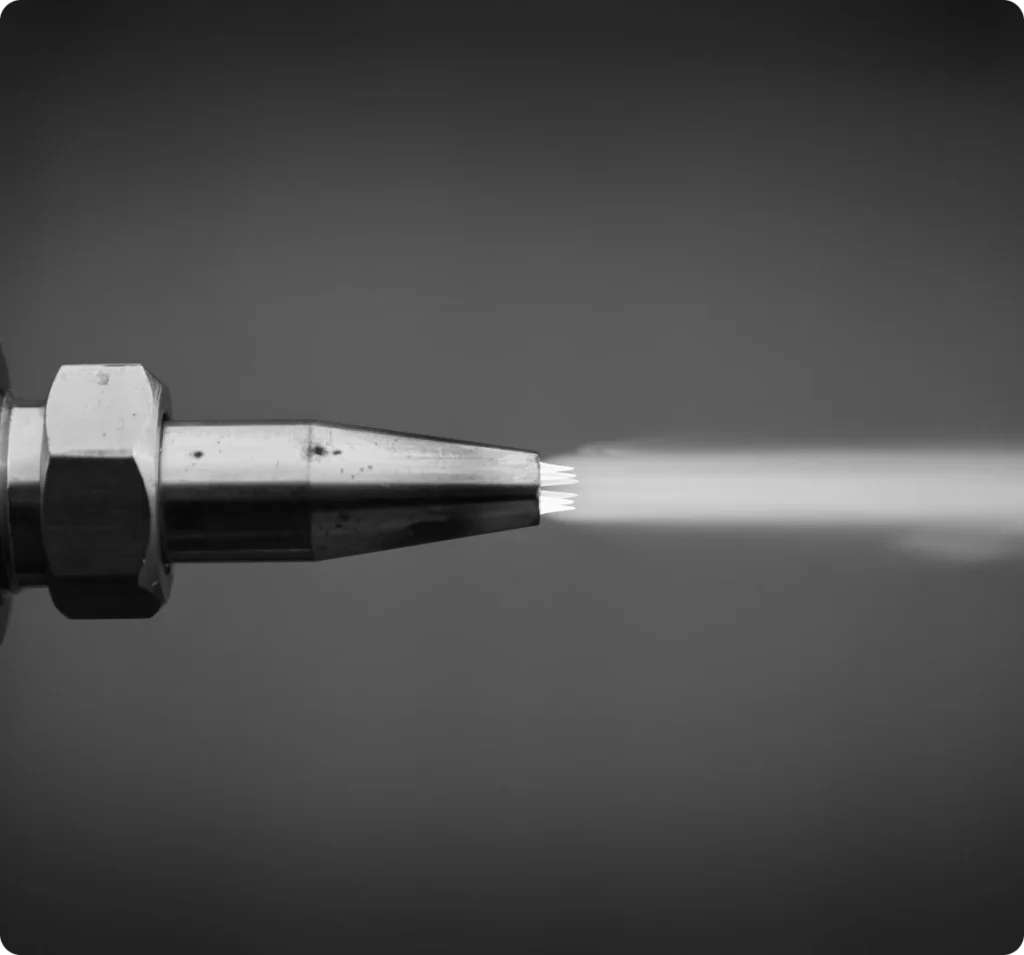

Our electroless nickel plating (ENP) service is engineered to deliver consistent, high-spec protection for parts exposed to abrasive, corrosive or high-stress conditions. Unlike traditional electroplating, ENP produces a perfectly even, conformal coating across the entire part surface with external, internal and intricately shaped areas included. This makes it ideal for precision components with tight tolerances, complex geometries or where uniformity of performance is non-negotiable.

The benefits of ENP

Electroless nickel plating is an autocatalytic process with no electricity required. Instead, the coating forms via a controlled chemical reaction that evenly deposits a nickel-phosphorus alloy onto the substrate. This uniformity is what gives ENP its edge, particularly where conventional plating or spray coatings fall short.

Regardless of the industry or application, our ENP delivers measurable performance.

When heat treated, it significantly increases in hardness, making it a durable alternative to hard chrome with none of the regulatory or environmental concerns.

- Highly uniform coating with no edge build-up, ideal for fine features and bores

- Excellent corrosion protection in chemically aggressive or salt-laden environments

- Hard-wearing surface that resists abrasion, erosion and contact fatigue

- Consistent, scalable process for both volume production and bespoke components

What sets our service apart

At Hardide, we tailor the choice of ENP chemistry to suit the specific requirements of each application, ensuring the best balance of protection and durability. We can provide high-phosphorus ENP for superior corrosion resistance, medium-phosphorus ENP for a balance of hardness and durability or low-phosphorus ENP for enhanced wear resistance.

Seamless integration or standalone finish

Hardide ENP can be specified as a standalone surface finish for corrosion and wear protection, a base layer under Hardide CVD coatings to optimise adhesion, or a final finish. Our expertise in combining ENP with other coating technologies ensures the right performance outcome, no matter your industry or operating conditions.

Ready for Precision-Prepared Surfaces?

Our advanced cleaning and degreasing services are engineered for coating integrity and in-service reliability. Whether you’re dealing with intricate geometries or preparing for Hardide coatings, we’re here to ensure your components meet the highest standards of cleanliness. Speak with our experts to explore how we can support your coating or inspection process with precision surface preparation.