Internal surface coatings

The Chemical Vapour Deposition (CVD) application process allows the uniform coating of internal and out-of-sight surfaces.

The Chemical Vapour Deposition application process

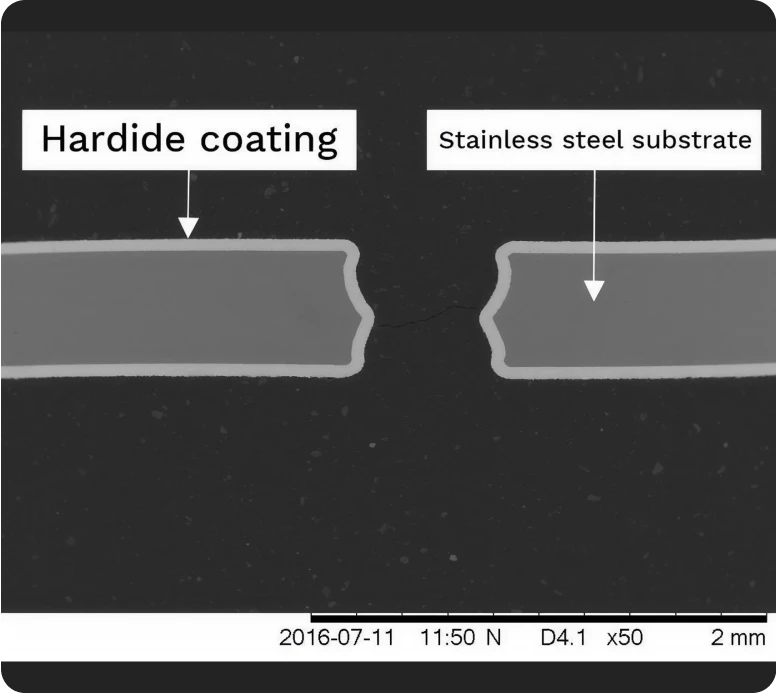

Two sided stamped hole

Section of coated steel plate with 0.6 mm diameter stamped hole. The Hardide coating uniformly covers both sides of the plate and inside the hole following its profile.

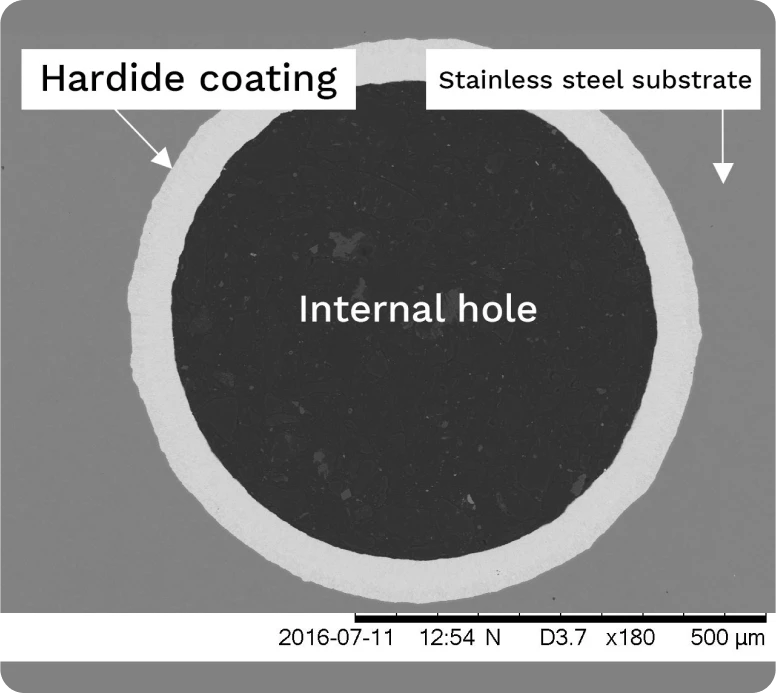

Step area

Another coated 0.6 mm diameter hole sectioned along the plate plane shows the Hardide coating is uniform around the hole circumference.

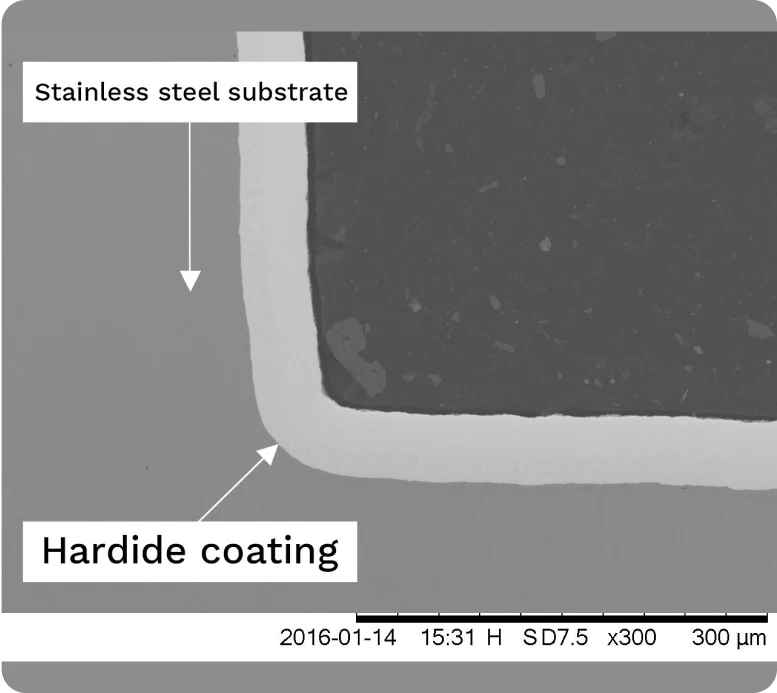

Internal and external corners

Internal corner coated with Hardide coating. Many traditional coating technologies would form a thinner layer in the internal corner.

The ability to coat internal diameters and complex shapes such as actuator threads, hydraulic cylinders, valves and pumps means engineers can revise designs and increase component complexity in the knowledge that the coating can be applied exactly where it is needed.

Hardide coatings are deposited uniformly and conformally, and can be targeted on external and internal surfaces, including complex geometries, where other hard face coatings such as HVOF and hard chrome plating cannot be applied.